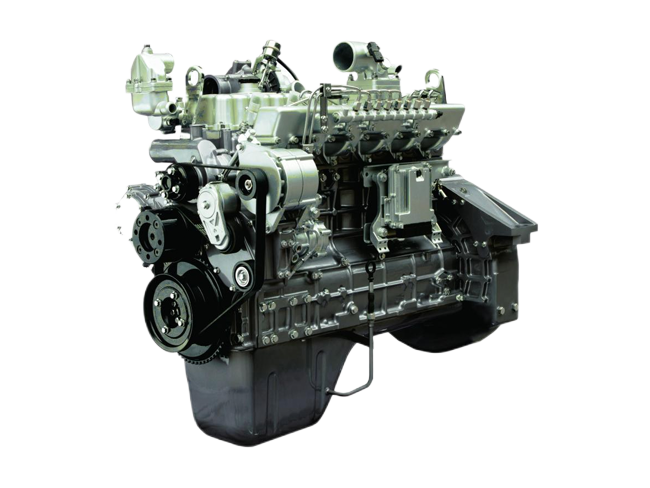

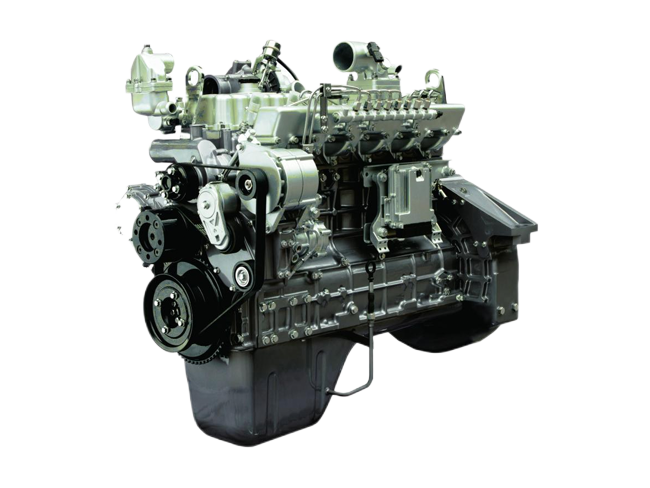

Design of a high-strength gantry structure, ensuring a solid and reliable engine block

Reliability development in strict accordance with FEV's mechanical development programs

Stepped connecting rod design, ensuring a higher pressure bearing capacity at the connecting rod small end and improving the reliability

Use of a 2-hole piston with an internal cooling oil passage

Application of comprehensive simulation calculation (CAE analysis), ensuring the reliability of parts

Application of an advanced high pressure common rail (HPCR) fuel system and Yuchai's patented in-cylinder combustion technology, effectively improving the engine power and torque, and maximizing the load-carrying capacity of vehicles

Application of Yuchai's patented efficient combustion technology, achieving a minimum fuel consumption of 193 g/kwh

Road spectrum collection and fine calibration according to market segment and applications, ensuring fuel economy

Use of an intelligent fuel-saving switch: The position switch is adjusted according to the real-time load, allowing the vehicle to operate in the economical range all the time, thus reducing the fuel consumption by at least 10%

Torque at 900 rpm: 820 N.m; maximum torque: 950 N.m

23% higher than the low-speed torque of competitors and 6% higher than the maximum torque of competitors, ensuring faster starting, easier overtaking and more efficient operation

Maximum speed control — be able to protect the engine from any damage due to excessive mechanical stress or thermal load

Limp home — be able to reduce the power in case of a fault in the electronic control system, ensuring that the vehicle can be driven to the maintenance station nearby

Low oil pressure protection — real-time monitoring and automatic fault diagnosis, achieving higher driving safety

Thermal protection — automatic torque limiting and overheating protection

Use of a thickened gear chamber cover, putting to an end to deformation

Change of the U-bolt groove structure between the cylinder heads of cylinders 3 and 4 to a new pressing block, improving the reliability of cylinder gasket

Heat shield of exhaust pipe and heat shield of turbocharger

Optimized air compressor speed ratio, reducing vibration

Use of a three-section exhaust pipe and a double-grid connecting rod bearing bush, achieving an increase in explosion pressure resistance by 15% and stronger deformation resistance

| Product Series | 6JA-50 | ||||

| Model Series | YC6JA180-50 | YC6JA200-50 | YC6JA220-50 | YC6JA240-50 | YC6JA260-50 |

| Displacement (L) | 6.87 | ||||

| Bore × Stroke | 108×125 | ||||

| Number of Valves per Cylinder | 2 | ||||

| Emissions | Euro Ⅴ | ||||

| Power (kw/rpm) | 132/2300 | 147/2300 | 162/2300 | 177/2300 | 191/2300 |

| Torque (N.m/rpm) | 700/1200~1700 | 800/1200~1700 | 860/1200~1700 | 950/1200~1700 | 1000/1200~1700 |

| Fuel System | BOSCH high pressure common rail system | ||||

| Exhaust Aftertreatment | SCR | ||||

| Dry Weight (kg) | 760 | ||||

| Oil Change Cycle | 20,000 (standard) | ||||

| B10 Service Life (10,000 km) | 70 | ||||