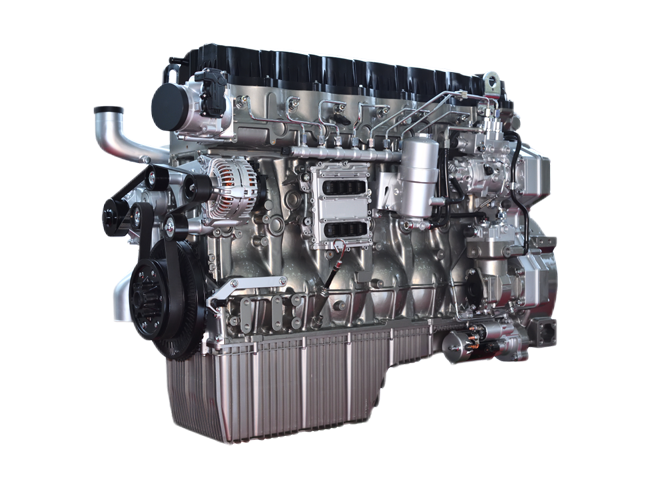

250bar ultra-high explosion pressure of the body

TOP-DOWN double cooling

Forged steel crankshaft

Lozenge arrangement of four valves

Long B10 service life, which is up to 1 million km ~ 1.6 million km

Fuel injection pressure of 2,000 bar

Overhead camshaft

High-efficiency turbocharger

High-efficiency mixed combustion system

High-efficiency combustion system

Low-friction structures and accessories

Maintenance interval of 20,000 km/60,000 km (optional)

Application of high-strength materials

Application of aluminum alloy parts and plastic parts

Platform-based and integrated modular design

Weight reduction by 20%~30%

Structure with high stiffness and low vibration

Dynamic balance control of crankshaft and eccentric design of piston

Plastic cylinder head cover + oil pan

High-precision grinding gear + anti-backlash gear

| Product Series | K13 | ||||

| Model Series | YC6K1349-50 | YC6K1352-50 | YC6K1354-50 | YC6K1355-50 | YC6K1356-50 |

| Displacement (L) | 12.939 | ||||

| Bore × Stroke | 129×165 | ||||

| Number of Valves per Cylinder | 4 | ||||

| Emissions | Euro Ⅴ | ||||

| Power (kw/rpm) | 360/1900 | 383/1900 | 397/1900 | 412/1900 | 426/1900 |

| Torque (N.m/rpm) | 2300/1000~1500 | 2400/1000~1500 | 2450/1000~1500 | 2500/1100~1500 | 2550/1100~1500 |

| Fuel System | Bosch common rail fuel system | ||||

| Exhaust Aftertreatment | SCR | ||||

| Dry Weight (kg) | 1100 | ||||

| Oil Change Cycle | 20,000 (standard); 60,000 (optional) | ||||

| B10 Service Life (10,000 km) | 160 | ||||